راتنج بو لصنع النعال والصندل

أحصل على آخر سعر| الدفع نوع: | L/C,T/T,D/P |

| إنكوترم: | FOB,CFR,CIF |

| أدني كمية الطلب: | 1000 Kilogram |

| نقل: | Ocean |

| ميناء: | Shanghai |

| الدفع نوع: | L/C,T/T,D/P |

| إنكوترم: | FOB,CFR,CIF |

| أدني كمية الطلب: | 1000 Kilogram |

| نقل: | Ocean |

| ميناء: | Shanghai |

نموذج: XC-2260/XC-8580

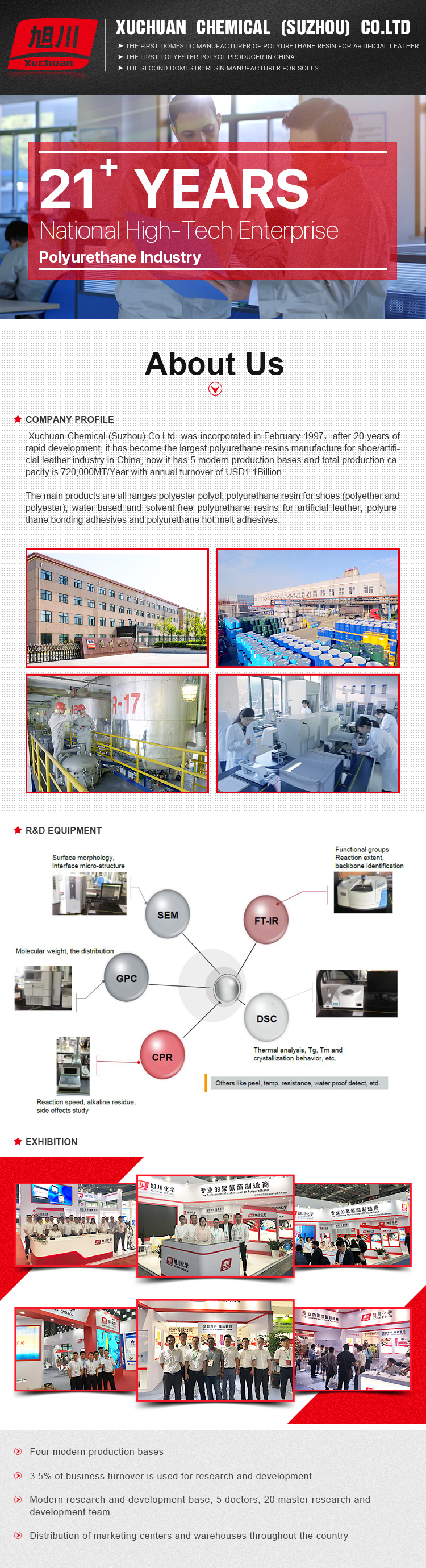

علامة تجارية: كيميائية Xuchuan

Application: Shoes

مكان المنشأ: الصين

انواع من: الراتنج الصناعي والبلاستيك

Code: XC-2260/XC-8580

Characteristic: Good handle, low density and good dimension stability

Appearance: liquid

راتنج بو لصنع النعال والصندل

حذاء SOLE PU CHEMICAL

| Application | shoe sole |

| Cream Time (s) | 6~8 |

| End of Rise Time (s) | 40~50 |

| Free Rise Foam Density(g/cm3) | 0.15~0.25 |

| Mold Temperature(℃) | 45~55 |

| Demold Time(min) | 2.5~3.5 |

| Molded Density (g/cm3) | 0.30~0.45 |

| Hardness(Shore A ) | 43~58 |

| Tensile strength(MPa) | 1.5~4.5 |

| Elongation(%) | 250~400 |

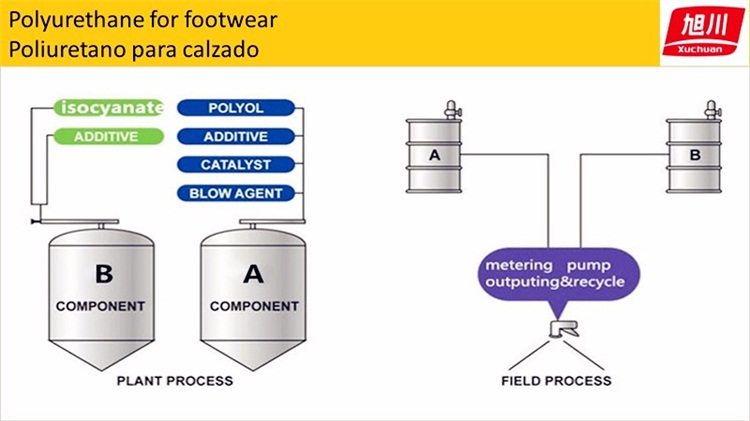

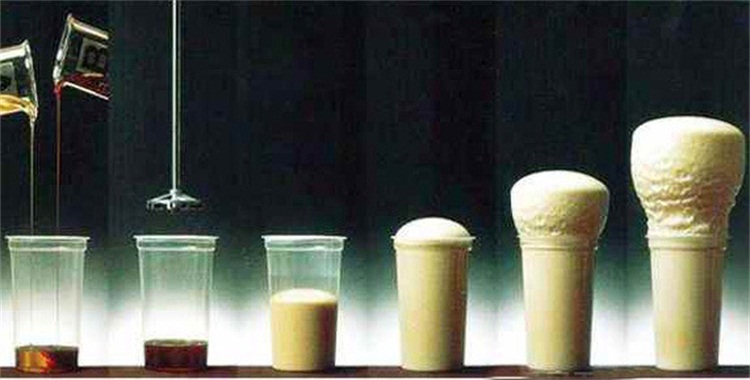

البولي يوريثان من أجل الأحذية النعل:

الكثافة: 300 ~ 500 كجم/م 3.

صلابة: 45 ~ 75Shore A.

توافق جيد مع الأصباغ.

نسبة على نطاق واسع.

|

Characteristic: Good handle, low density and good dimension stability |

|||||||

|

Application: Outsole and mid-sole |

|||||||

|

Typical properties of PU matrix |

|||||||

|

Name of products |

Appearance |

Viscosity (mPa·s/40℃) |

Density (g·cm-3/40℃) |

Package(kg) |

/ |

/ |

/ |

|

A-2260 |

Cream white liquid |

800~1200 |

1.01~1.02 |

18 |

/ |

/ |

/ |

|

B-8580 |

Yellowish transparent liquid or waxy |

600~800 |

1.08~1.2 |

20 |

/ |

/ |

/ |

|

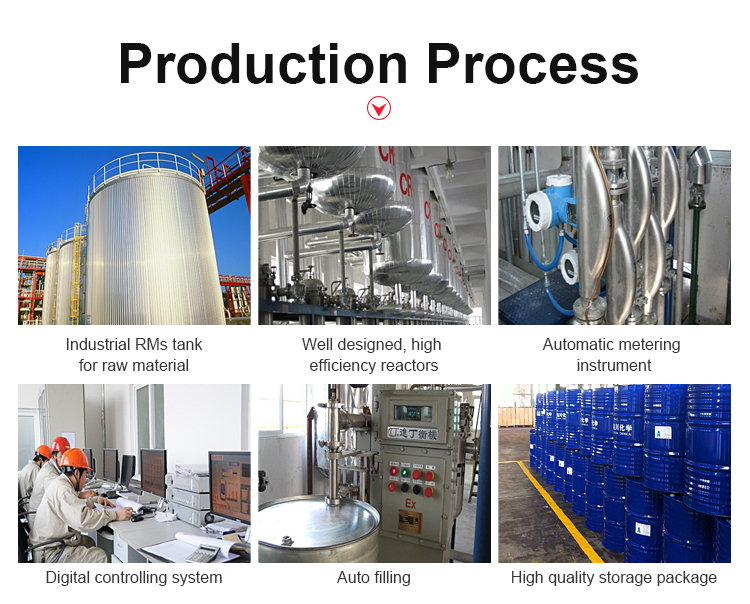

Materials preheat |

|||||||

|

A-2260: preheated at 50~60℃ for 8~10 hours |

|||||||

|

B-8580: preheated at 50~60℃ for 8~12 hours |

|||||||

|

Typical processing parameters & Reaction parameter |

|||||||

|

Items |

A/B Materials Temperatures(℃) |

A+C/B Mix ratio (By weight) |

Cream Time (s) |

End of Rise Time (s) |

Free Rise Foam Density(g/cm3) |

Mold Temperature(℃) |

Demold Time(min) |

|

Parameter |

40~45/38~42 |

100/96~98 |

6~8 |

40~50 |

0.15~0.25 |

45~55 |

2.5~3.5 |

|

The adding content of C-2 should be 270g±20g/18kg |

|||||||

|

The adding content of water should be 0~100g/18kg according to the reality |

|||||||

|

The adding content of hardener should be changed according to the reality |

|||||||

|

Physical properties |

|||||||

|

Items |

Molded Density (g/cm3) |

Hardness (Shore A ) |

Tensile strength (MPa) |

Elongation (%) |

Tear Strength (kN/m) |

Ross Flexing (room temperature) ( 40,000 times) |

/ |

|

/ |

|||||||

|

/ |

|||||||

|

Physical properties |

0.30~0.45 |

43~58 |

1.5~4.5 |

250~400 |

10~26 |

No crack |

/ |

|

Demold time may be prolonged with the increase of sole thickness |

|||||||

|

These physical data are acquired by testing a sample of 6mm thick. |

|||||||

|

Data listed above are just for reference. The detail data are subjected to practical production. If other requests for physical properties, please contact us. |

|||||||

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.