بوليول وإيزوسيانات لحذاء إسفين سيدة

أحصل على آخر سعر| الدفع نوع: | L/C,T/T,D/P |

| إنكوترم: | FOB,CFR,CIF |

| أدني كمية الطلب: | 1000 Kilogram |

| نقل: | Ocean |

| ميناء: | Shanghai |

| الدفع نوع: | L/C,T/T,D/P |

| إنكوترم: | FOB,CFR,CIF |

| أدني كمية الطلب: | 1000 Kilogram |

| نقل: | Ocean |

| ميناء: | Shanghai |

نموذج: XC-9080W/XC-6088W

علامة تجارية: Xuchuan الكيميائية

مكان المنشأ: الصين

Application: Outsole, slippers, wedge shoes

Code: XC-9080W/XC-6088W

Keywords: water soluble polyurethane resin

Appearance: Liquid

Characteristic: Low density and high hardness, good appearance, little pinhole, and weak foam line

| Application | shoe sole |

| Keywords | water soluble polyurethane resin |

| A/B Materials Temperatures(℃) | A/B Materials Temperatures(℃) |

| A+C/B Mix ratio (By weight) | 100/100~102 |

| Cream Time (s) | 6~8 |

| End of Rise Time (s) | 30~40 |

| Free Rise Foam Density(g/cm3) | 0.21~0.26 |

| Mold Temperature(℃) | 45~55 |

| Demold Time(min) | Demold Time(min) |

| Molded Density (g/cm3) | 0.35~0.60 |

|

Characteristic: Low density and high hardness, good appearance, little pinhole, and weak foam line |

|||||||

|

Application: Outsole, slippers, wedge shoes |

|||||||

|

Typical properties of PU matrix |

|||||||

|

Name of products |

Appearance |

Viscosity (mPa·s/40℃) |

Density (g·cm-3/40℃) |

Package(kg) |

/ |

/ |

/ |

|

A-9080W |

Cream,White,liquid |

1000~1300 |

1.01~1.02 |

18 |

/ |

/ |

/ |

|

B-6088 |

Yellowish transparent liquid or waxy |

600~800 |

1.08~1.2 |

20 |

/ |

/ |

/ |

|

Materials preheat |

|||||||

|

A-9080W: preheated at 50~60℃ for 6~8 hours. |

|||||||

|

B-6088: preheated at 50~60℃ for 6~8 hours. |

|||||||

|

Typical processing parameters & Reaction parameter. |

|||||||

|

Items |

A/B Materials Temperatures(℃) |

A+C/B Mix ratio |

Cream Time (s) |

End of Rise Time (s) |

Free Rise Foam Density(g/cm3) |

Mold Temperature(℃) |

Demold Time(min) |

|

Parameter |

40~45/38~42 |

100/100~102 |

6~8 |

30~40 |

0.21~0.26 |

45~55 |

5~7 |

|

The adding content of C-2 should be 210g±10g/18kg. |

|||||||

|

The adding content of water should be 0~80g/18kg according to the reality. |

|||||||

|

The adding content of hardener should be 0~1200g/18kg according to the reality. |

|||||||

|

Physical propertiesShoe Sole Pu Chemical |

|||||||

|

Items |

Molded Density (g/cm3) |

Hardness |

Tensile strength |

Elongation |

Tear Strength |

Williams abrasion |

/ |

|

Physical properties |

0.35~0.60 |

60~88 |

4~7 |

200~300 |

11~20 |

130~200 |

/ |

|

Demold time may be prolonged with the increase of sole thickness. |

|||||||

|

|

|||||||

|

|

|||||||

يتم الحصول على هذه البيانات المادية عن طريق اختبار عينة من سمك 6 مم.

البيانات المذكورة أعلاه هي فقط للرجوع إليها. تتعرض بيانات التفاصيل للإنتاج العملي. إذا كانت طلبات أخرى للخصائص الفيزيائية ، يرجى الاتصال بنا.

نظام PU للحذاء النعل ، لاصق للأحذية ، وحدة المعالجة المركزية ، TPU ، بوليستر بوليول ، راتنج PU للحبر ، لاصق ذوبان الساخن ، لاصق للحزمة المرنة ، راتنجات بو الاصطناعية

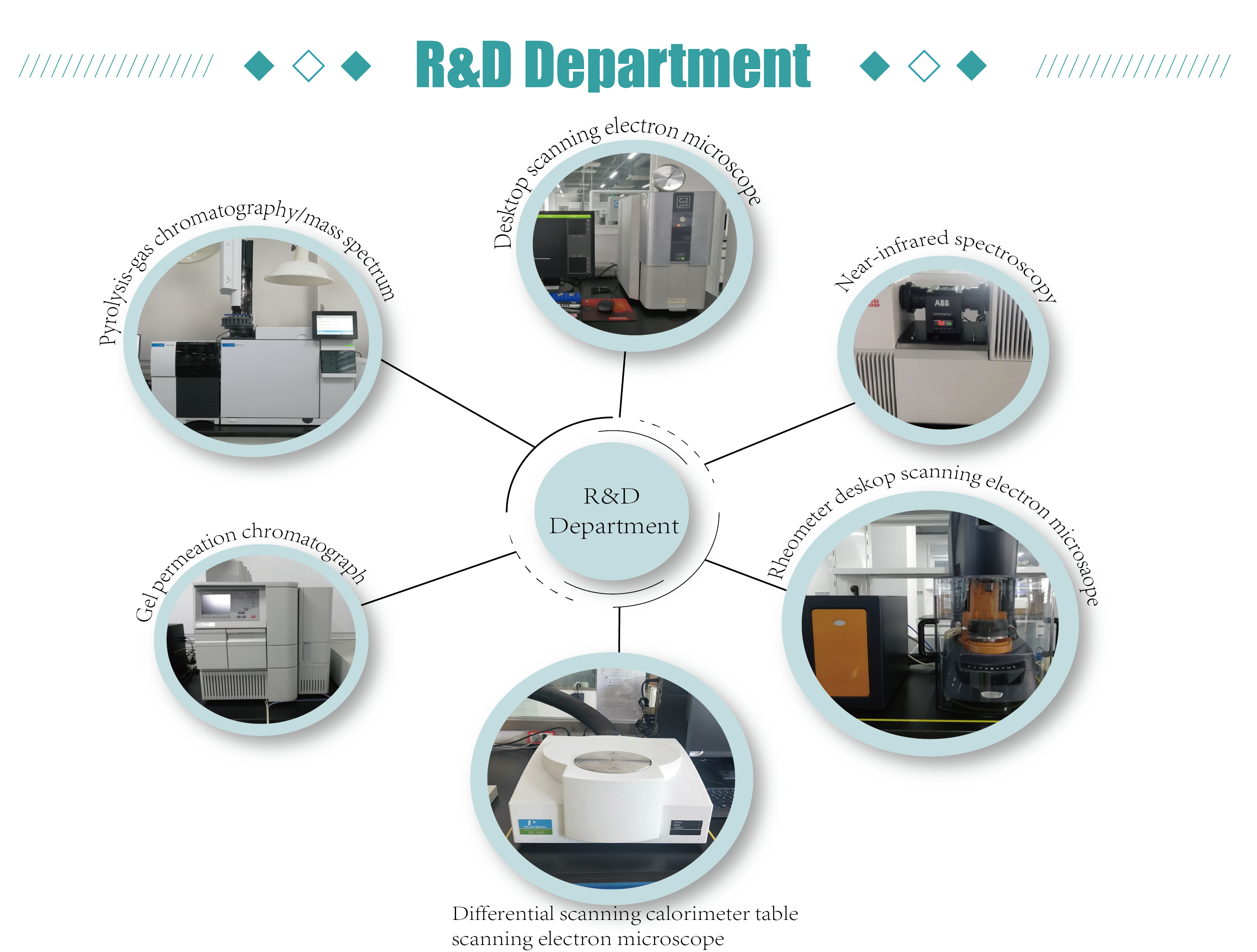

Xuchuan Chemical تأسست في عام 2007 ، تبلغ شركة Company المسجلة Capital 500 مليون يوان. جميع المنتجات الرئيسية هي النطاقات البوليستر البوليستر ، وراتنج البولي يوريثان للأحذية ، وراتنجات البولي يوريثان القائمة على الماء وخالية من المذيبات للجلد الاصطناعي ، والمواد اللاصقة للترابط البولي يوريثان ، والمواد اللاصقة الساخنة للبولي يوريثان.

الآن لدى Xuchuan 4 قواعد إنتاج حديثة ، وصلت الطاقة الإنتاجية إلى 630،000 طن سنويًا ، وتم تصدير المنتجات إلى 32 دولة ومنطقة في العالم.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.